Formulating BioPesticides: The LabCoat Guide to Pesticides & BioPesticides

In this eighth article in the LabCoat Guide to Pesticide Mode of Action, I discuss Biopesticide Formulation and its importance as a factor in determining the commercial success of a biopesticide candidate.

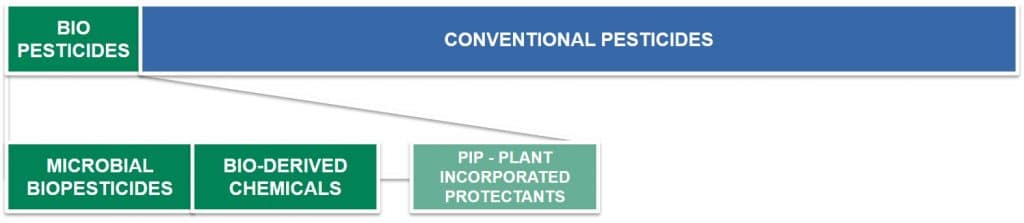

Biopesticides are pesticides based on microorganisms or natural products. Biopesticides fall into three major classes:

Microbial pesticides, including the biopesticidal metabolites produced by these organisms

Bio-derived chemicals (metabolites) are naturally occurring compounds, and include:

• Semiochemicals – natural compounds such as pheromones, released by an organism that affect the behaviour of other organisms

• Biocontrol compounds isolated from microorganisms (e.g. Spinosad)

• Biocontrol compounds isolated from fungi or crustacean shells, such as Chitosan

• Plant extracts, including secondary biocontrol metabolites such as alkaloids, terpenoids and phenolics

• Naturally occurring minerals – such as silicates – with biocontrol activity

Plant-incorporated protectants (PIPs) comprising foreign DNA inserted into crop genetic material (GM crops).

For this discussion of biopesticide formulation, our attention will focus on the first two classes:

As for conventional pesticides, formulation of biopesticides comprises the blending of a biologically active metabolite or microorganism with a carrier or solvent as well as adjuvants, to develop a product which can be delivered to the target weed, pathogen or pest using existing equipment.

The objectives of biopesticide formulation are to stabilize the active metabolite or microorganism, to optimize delivery to the target, to protect the biopesticide during storage and in the field, and to enhance the efficacy of the biopesticide.

Unique Requirements and Challenges for Biopesticide Formulation

The biological activity or mode of action of a pesticide is determined by its biologically active microorganism or metabolite. The active ingredient in its raw form requires formulation to facilitate its handling, storage and application.

A key difference between the formulation of conventional (chemical) pesticides and the formulation of biopesticides is the living nature of the biopesticide, and their biological viability is sensitive to storage conditions and environment.

A challenge for the formulation of microbial biopesticides is the presence of additional fermentation materials besides the microbes themselves. These materials may adversely react with formulation ingredients.

Another challenge facing microbial biopesticide formulators is the tendency for gram-positive bacteria such as Bacillus spp. to produce a slime layer in connection with endospore formation. Suspension of these bioformulations for spraying can lead to excessive sliminess and the blockage of sprayer filters and nozzles. While the slime layer is removable e.g. by centrifugation, it may contain valuable components such as lipopeptides, which may contribute to the biopesticidal effect.

Shelf life (storage stability)

Other challenges to biopesticide formulation include the shorter shelf life of biopesticides compared to conventional pesticides. Significant formulation efforts are being targeted at the long-term stabilization of microbial and other biopesticides.

Shelf life measured in years is normal for conventional plant protection products, while for biopesticides a shelf life of 1 to 2 years is desirable. For many biopesticides, however, shelf life is measured in weeks, and the correct storage of these products is vital. This is especially important for non-spore-forming, gram-negative bacteria.

Shelf life and viability may be extended by reducing storage temperature through freezing or refrigeration. While refrigeration is not an option in most cases, exceptions do exist for high-value crops, and there appears to be a growing tendency for growers to treat biopesticides as perishable high-value products.

Microorganisms may be frozen or refrigerated in culture broth or an appropriate buffer. However, depending on the microorganism, storage in culture broth may impact long-term cell viability, and extensive testing and development in this area is currently a priority.

Besides storage, longer shelf life may be obtained by increasing the number of microorganisms in the product, to ensure viability despite a subsequent decline in their population.

Fermentation parameters such as the rate of dehydration and the physiological state of the bacteria on harvest from the medium will also affect the shelf life of the final formulation.

Semiochemicals

Semiochemicals – natural compounds such as pheromones – are difficult to formulate due to their volatility. Their encapsulation in traditional polymer matrixes or natural biological microcapsules such as yeast cells may reduce their volatility and degradation by facilitating their controlled release to the environment.

However, as microcapsules are about the same size as pollen grains, microencapsulated biopesticides may pose a hazard to foraging bees. These may carry the microcapsules back to their hives where the biopesticide is released, with the risk of harming the bees.

Delivery

Due to the particulate nature of most biopesticides, agitation of the spray suspension is vital to prevent precipitation in the spray tank. Biopesticides are formulated for use with standard application equipment, and additional levels of filtering and straining as well as the use of large-orifice nozzles are recommended to prevent clogging.

Biopesticides are exposed to detrimental environmental conditions when applied in the field, including sunlight (UV), fluctuating moisture conditions, plant physiological and biochemical responses as well as competition by microorganisms already present on the leaf surface. These conditions may lead to shorter persistence once the biopesticide is applied to crops (field persistence).

UV-stability may be addressed by the addition of protectants (sunscreens such as oxybenzone and light blockers, such as lignin), the inclusion of antioxidant-rich natural products, and through the encapsulation of the active metabolite or microorganism.

Future developments are expected to include expression of genes coding for enzymes involved in DNA repair. In addition, an understanding of crop physiology may be used to reduce the exposure of biopesticides to sunlight, e.g. by utilizing the physiology of maize leaf whorls to funnel biopesticide granules to the feeding sites of larvae.

Since many biopesticides are slow to control the pest or pathogen, growers may feel that the product has insufficient effect and reapply unnecessarily. Diligent reading of labels and an understanding how the product works, as well as appropriate scouting is necessary for the optimal application of these products, allowing growers to reap the full benefits of biopesticides and attain consistent results.

Formulation types

Due to differences in environmental conditions, biopesticides may be formulated in different forms, each designed for a specific market. Many of the formulation types described in the previous articles on conventional pesticide formulation are relevant for biopesticides.

Most biopesticides are formulated as dry (solid) formulations. Dry formulations of dormant bacterial spores tend to have a longer shelf life compared to most liquid formulations. Dry formulations may, however, have several disadvantages, including lower field performance and the risk of nozzle blockage.

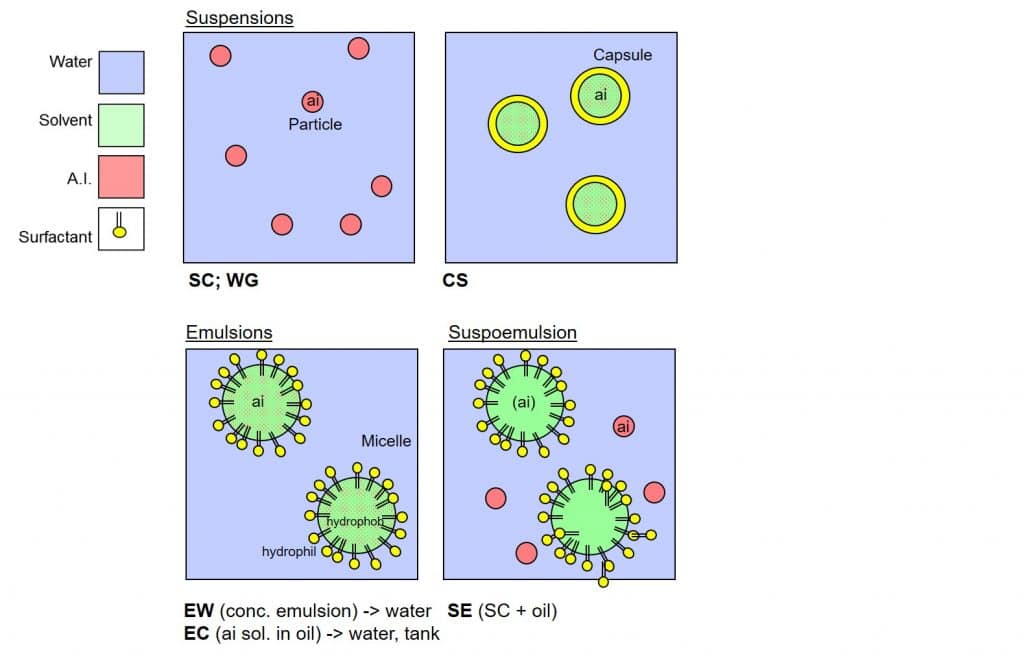

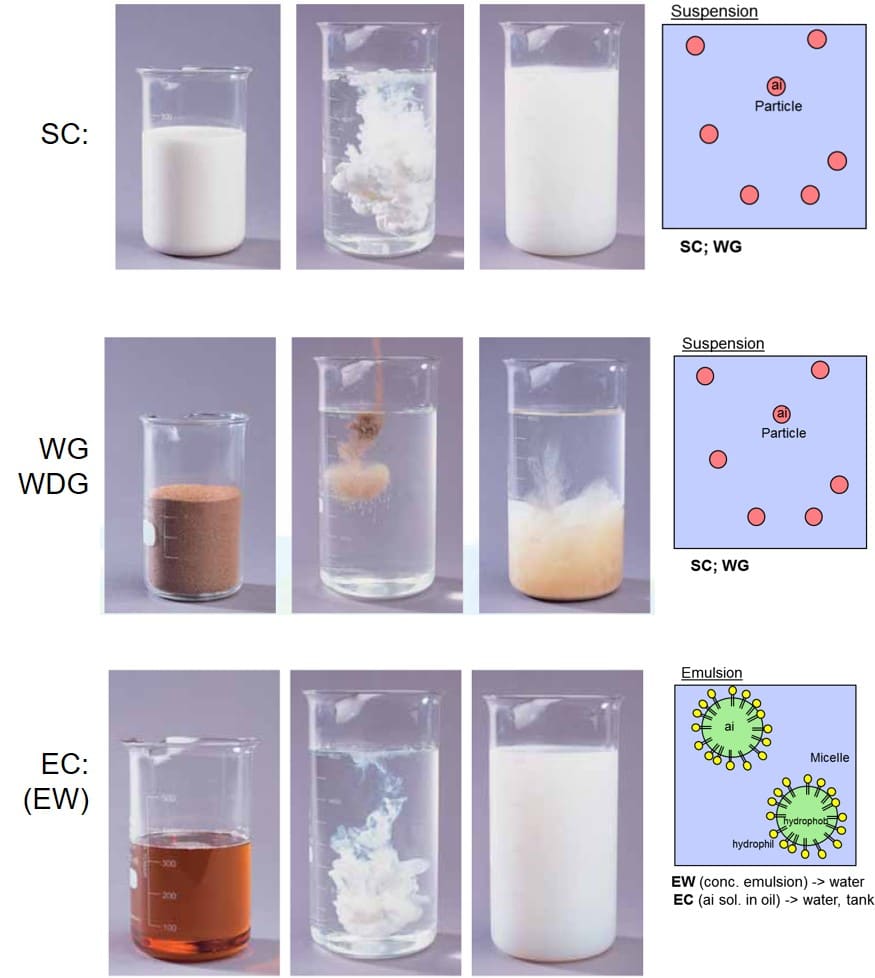

Figure 1: Summary of selected formulation types in aqueous spray solutions.

Dry products include: dusts (to be applied dry), wettable powders (WP; intended to be applied as an aqueous suspension) and granules (G), which may be applied directly or mixed as an aqueous suspension (water dispersible granules; WG or WDG).

Liquid biopesticide formulations typically comprise biopesticidal metabolites or microorganisms suspended in a medium containing adjuvants, protectants and nutrients.

They may be formulated as conventional formulations such as suspension concentrates (SC) or as cell suspensions in water, oils or combinations of both (emulsions; EC or EW) and microcapsules (CS).

Figure 2: Suspensibility (SC; WG) and solubility (EC; EW) of pesticide formulations. Photos used with permission: Bayer AG, Leverkusen, Germany.

Liquid biopesticide formulations address issues regarding shelf life and field efficacy, and may generally be applied using existing field equipment without issue. The latter is of importance for the acceptance of biopesticides by growers, who usually are not willing to invest in new equipment specifically for the application of biopesticides.

Inerts

Formulation components other than the active ingredient or microorganism are called inerts. Inerts may contribute to improving product performance by optimising contact to leaf, soil or insect surfaces, by reducing desiccation, by increasing shelf life or by increasing solubility or suspensibility in water.

Inerts can include dry carriers (mineral: e.g. clay, or organic: e.g. flour) or liquid carriers (e.g. vegetable oils) as well as binders, desiccants, thickeners, surfactants, stickers and UV protectants. Formulation carriers can affect survival and viability, by affecting both drying-survival and storage stability.

To ensure microbial survival and efficacy after delivery, formulations may contain carbon sources (nutrients) such as molasses or peptone and moisture-retaining polymers. Hydrogels consist of a network of hydrophilic polymer chains which can hold large amounts of water.

Hydrogels may be used in slow-release biopesticide formulations to improve nutrient and moisture retention as well as reduce degradation, leading to improved biopesticide viability and efficacy.

For biopesticides, it is important that formulation inerts have low toxicity, both from an environmental and health perspective, but also with respect to the viability of the microorganism being formulated. Chitosan is often included in biopesticide formulations (for example, in hydrogel formation), and its possible antibacterial effects must be considered when formulating microbial biopesticides.

Trends

The trend in conventional and biopesticide formulation is to move away from dusts, wettable powders and suspension concentrates to water dispersible granules.

Controlled release formulations are being developed to optimise effect, while nanotechnology is expected to provide new types of formulations such as nanoemulsions, nanosuspensions and nanocapsule formulations.

Another area of focus is the choice of appropriate adjuvants for optimal biopesticidal activity. Here, cooperation between biologists and chemists is facilitating the development and introduction of new formulations and applications, reducing the inconsistency of field performance and encouraging growers to implement this new technology.

Attention is also being given to delivery and application practices, specifically to understanding the impact of plant defence induction kinetics on application timing and placement.

Conclusion

Until recently, slow progress in formulation and delivery research has been a major hurdle to biopesticide development and acceptance. Current research efforts in bioformulation technology are focused on promoting the bioefficacy post-application, especially with regard to application timing and placement of the formulated product.

Formulation is one of the key factors in determining the commercial success of a biopesticide candidate. There are significant costs involved in solving the biological issues of biopesticide formulations (including storage and field stability as well as efficacy consistency), but the benefits in terms of market access and the acceptance of biopesticides as viable commercial alternatives or supplements to conventional plant protection products warrant this effort.

In the next article in this series, I discuss Formulation Adjuvants and their role in improving Pesticide and Biopesticide efficacy.

***

Thanks for reading – please help make LinkedIn great and enable me to produce more content by liking or sharing this article, making it visible to your network!

Please feel free to read and share my other articles in this series:

A little about myself

I am a Plant Scientist with a background in Molecular Plant Biology and Crop Protection.

20 years ago, I worked at Copenhagen University and the University of Adelaide on plant responses to biotic and abiotic stress in crops.

At that time, biology-based crop protection strategies had not taken off commercially, so I transitioned to conventional (chemical) crop protection R&D at Cheminova, later FMC.

During this period, public opinion gradually closed the door of opportunity for conventional crop protection strategies, while the biological crop protection technology I had contributed to earlier began to reach commercial viability.

From January 2018, I will be available to provide Strategic R&D Management as well as Scientific Development and Regulatory support to AgChem & BioScience organizations developing science-based products.

For more information, visit BIOSCIENCE SOLUTIONS – Strategic R&D Management Consultancy

Keywords: #cropprotection #biologicals #biopesticides #pesticides #formulation #plantscience #agchem #agbio #bioscience #authorpreneur #projectmanagement #biological #biopesticide #pesticide #R&D #strategy #consultant #strategic #management #executive #insead #srdm

***