STRATEGIC R&D MANAGEMENT PART I: Successful Biology-based Product Development – a Case Study

Strategic R&D Management case study presented by Harry Teicher at “R&D of AgriProducts: Exploring the next generation of AgriProducts”, Amsterdam 22-23 November, 2017.

The objective of this case study is to address issues commonly encountered at the interface between strategic management and expert teams involved in conventional– and biological crop protection development.

In the first part of this series on Strategic Research Management, the problems encountered through the implementation of a conventional development strategy for the development of a new biological product are presented.

In the second part, the learning process from Part I is applied to develop a new biological development strategy for the successful introduction of a new product line.

• Case Study of experiences developing a new biological product – what did we learn?

• To be successful, Strategic Management need to understand the biology involved.

• Why it is key that senior management from chemical companies and chemical backgrounds need to integrate biological expertise.

Background: Biologicals in Crop Protection

Global human population growth is around 75 million annually, and estimates place our total population at over 9 billion by mid 2050. The logistical issues include not only the projected 9 billion people, but also the estimated hundred billion head of livestock we will need to feed to maintain our current consumption standards.

In order to provide sufficient crop resources, new and innovative crop protection strategies are constantly being developed and implemented. These include formulation and application innovations for conventional pesticides (herbicides, insecticides and fungicides) as well as the development and application of economically viable agricultural Biologicals.

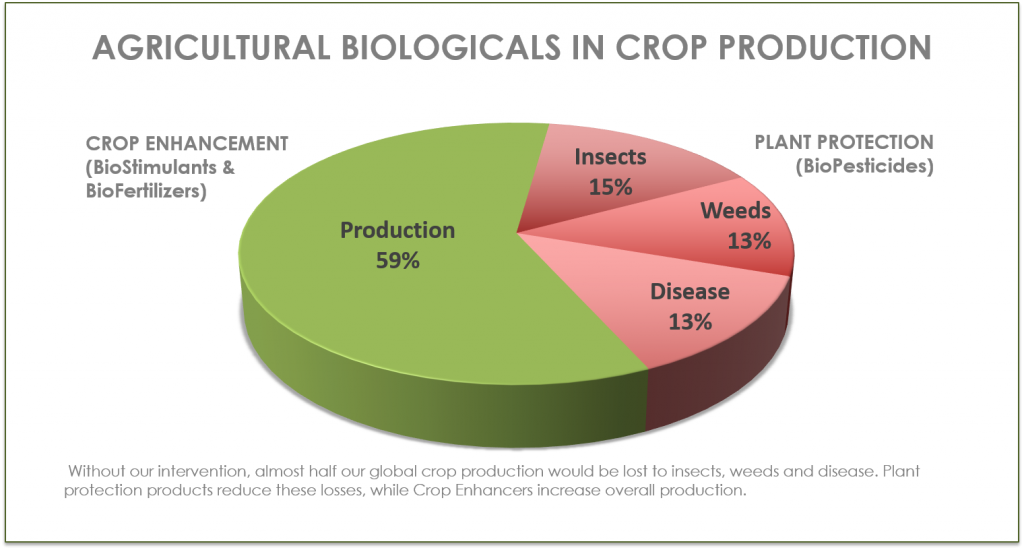

Without crop protection strategies, we would risk losing almost half of our overall crop production to insects, weeds and disease:

Figure 1: Plant Protection agents – including BioPesticides – reduce crop losses, while Crop Enhancement

agents (including BioStimulants and BioFertilizers) contribute to increasing overall crop production.

Agricultural Biologicals may be classified into three segments: BioPesticides, BioStimulants and BioFertilizers.

BioStimulants and BioFertilizers are defined as biological substances or microorganisms capable of promoting crop health by increasing the availability of nutrients, or by acting as plant strengtheners and phytostimulants.

BioPesticides are pesticides based on microorganisms or natural products. In a previous series of articles on BioPesticides, I focus on bridging the Interface between Biological and Conventional crop protection, define Agricultural Biologicals terminology, analyse their current viability and discuss drivers of BioPesticide efficacy.

Biologicals in crop protection are not a new innovation

My grandfather was famous for his mildew-free roses. Every spring, he would do the same as his grandfather: monitor weather conditions and – when he deemed the time to be right – sprinkle beer on his roses. While unable to provide a scientific explanation for his anti-mildew strategy, he never neglected a treatment (or beer, apparently!).

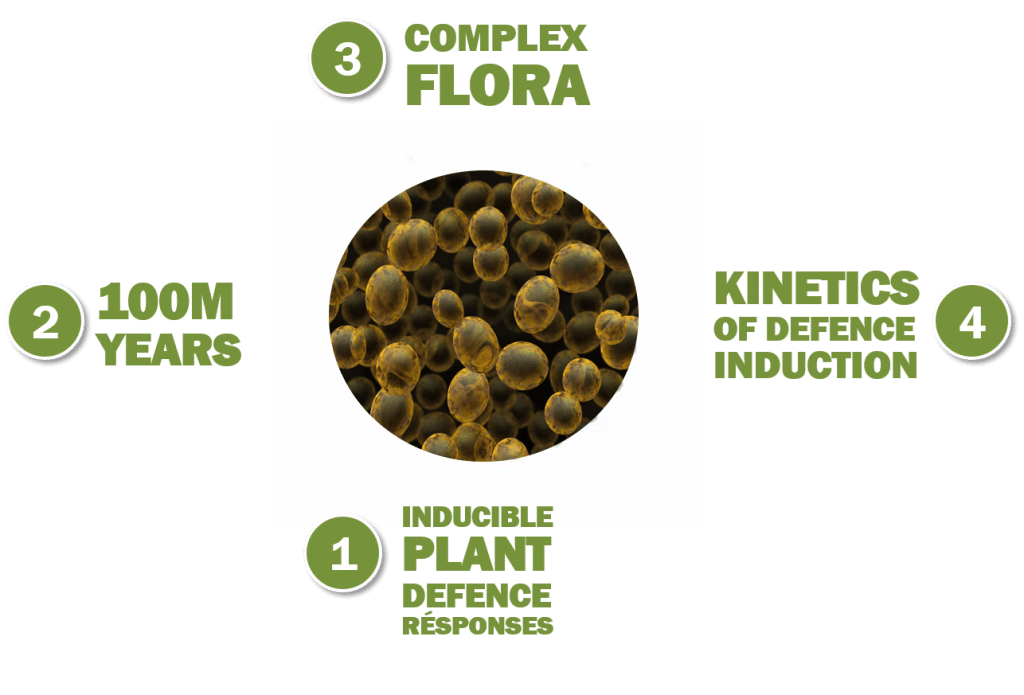

Today we understand that the application of fungal yeast cells to plant leaves leads to the induction of plant defence responses, as the plants believe themselves to be under invasion by a potential fungal pathogen.

Figure 2: Biologicals in crop protection.

The efficacy of biologicals is – to a large extent – driven by inducible plant defence responses evolved over more than 100 million years. These defence responses have proven to be sufficiently efficacious to allow the evolution of a complex flora.

Plants detect invading pathogens and induce defence responses, such as the production of toxic chemicals as well as cell destruction (hypersensitive responses), to hinder disease development.

Plant defence responses are not initiated until pathogens are detected, due to the energy costs of their production and maintenance. Modern BioPesticide strategies must thus take into account the kinetics of defence response induction prior to pathogen attack.

With the transition from complex natural flora to modern monoculture, the kinetics of disease and pest development exploded – outpacing the evolutionary development of natural plant defence responses and requiring the development of current conventional (chemical) crop protection products.

Although natural plant defences have not yet evolved to combat modern pest and disease pressures, the evolution in our understanding of their molecular mechanisms as well as their induction has.

In recent years, efficacy trials demonstrate conclusively that biology-based crop protection strategies can attain an efficiency at least on par with conventional crop protection strategies.

Case study: Biology-based Product Development in the Agrochemical Industry

DISCLAIMER: The following case study is fictitious and based on experiences and observations made across the crop protection industry, and does not represent the experiences of any specific company.

The case study begins with the initial strategy for the development of a new biological product by AGCHEMCO, a conventional (chemical) crop protection company. It presents and analyses the problems encountered through the implementation of a conventional development strategy, and describes how this learning process was applied to develop a revised biological development strategy.

***

In December 2013 Mary Walker, CEO of AGCHEMCO, hosted a meeting of the company’s senior management. The order of business was simple: future sales estimates for the company’s agrochemical products were in decline, and the immediate implementation of a revised business strategy was imperative.

Stricter pesticide regulatory requirements in the EU and Brazil had restricted market access and increased registration costs, while an associated decline in the number of registered active substances in the EU was reducing the viability of crop protection resistance strategies.

In addition to stricter pesticide regulatory requirements, consumer awareness regarding hazards caused by chemical pesticides, and the phasing-out of toxic conventional pesticides contributed to the decline in sales estimates – while at the same time driving the growth of the agricultural biopesticide market.

Walker presented an ambitious strategy: the immediate implementation of drastic cost-cutting measures and the culling of low-profit product lines to create a leaner, more effective organization.

In addition to optimizing its core business, AGCHEMCO would enter the rapidly growing biopesticide market by leveraging its existing agrochemical market access and development experience.

Negotiations to access a promising first-stage biological fungicide candidate had been succesfully completed, with the objective of completing in-house development and registration, and attaining market access within three years.

Walker’s strategic reasoning was sound. Estimates of global market sizes for crop protection products (conventional pesticides as well as biopesticides) varied, but the general consensus was that biopesticides were expected to increase from about 2% of the global pesticide market in 2003 to about 8% of the market (estimated to exceed 82 billion USD) in 2020.

The prevailing opinion was that the compound annual growth rate (CAGR) for biopesticides during this period was expected to exceed 12%, compared to an expected overall pesticide CAGR of about 7%.

Figure 3: AGCHEMCO CEO’s case for entering the Biopesticide market.

The proposed vision and strategy was received positively by Executive Management, and Jon Braun, VP of R&D for AGCHEMCO, was assigned the responsibility for its execution.

***

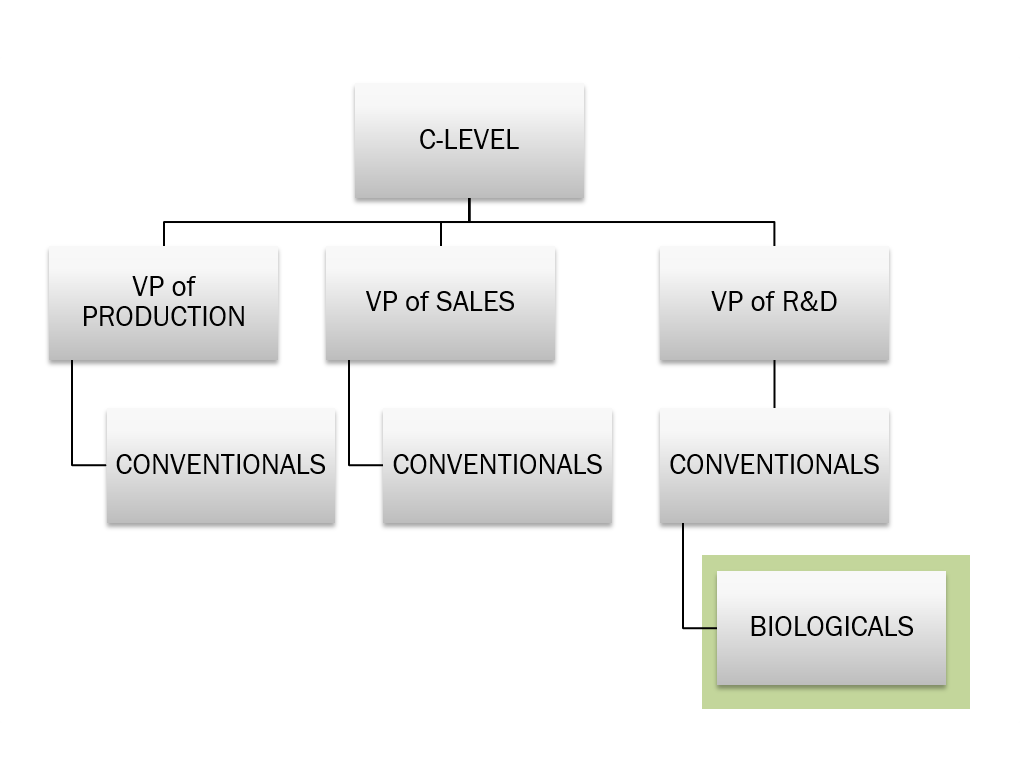

Braun’s first task was to incorporate a Biologicals project group into the existing R&D structure within the company’s conventional crop protection organizational framework:

Figure 4: Incorporation of the Biologicals Project group within the existing organizational framework.

Braun convened a meeting of the project group and introduced the new biofungicide candidate – an unformulated microbial fermentate. The acquired data package was sparse, and the only available efficacy data was from initial lab trials.

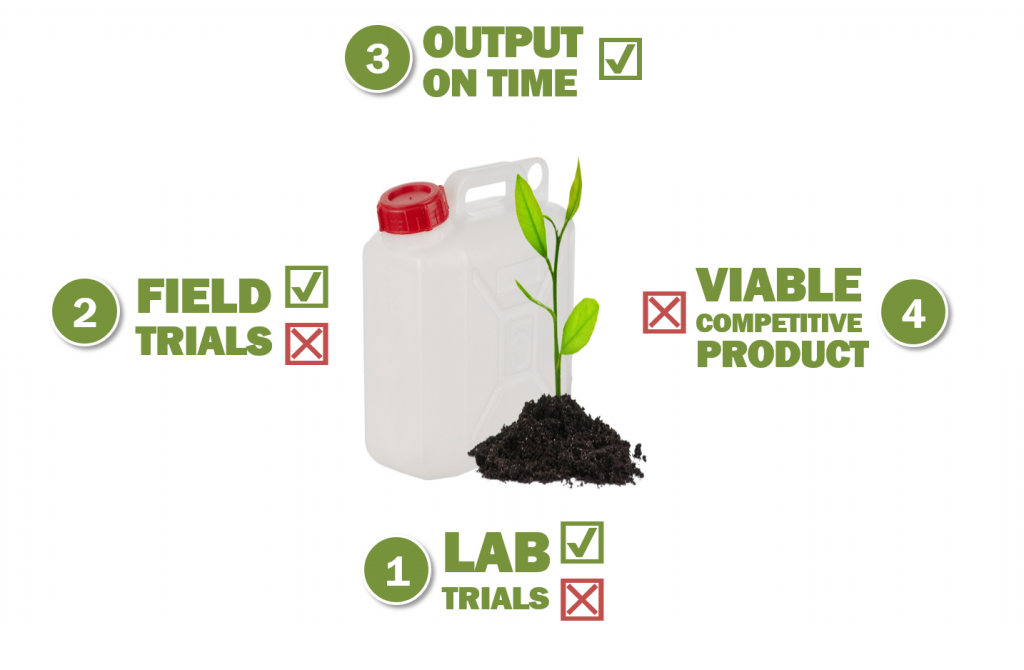

The objective of the project group was defined: the development of a viable, competitive product – successfully tested for efficacy under lab and field conditions.

The final product was to be registered and in the market in three years, leaving only twelve months for development. Standard project performance parameters – comprising milestone deadlines and KPIs – were defined to ensure that outputs would be reached on time.

To be successful, the biofungicide would need to compete in the cereal fungicide market, competing against conventional (chemical) products with both protective and curative activity.

Due to the perceived variability of biopesticide efficacy, the biofungicide candidate would need to work at least as well – and as consistently – in the field as the commercial competitors.

The meeting broke up, and over the following four months the Formulation group developed a stable formulation of the biofungicide, for which efficacy was confirmed in a series of initial agar-plate and leaf-disk assays.

***

Following the initial round of testing, whole-plant greenhouse and field trials were carried out. After the third set of greenhouse trials, Braun met with the project group.

The results were disappointing. The initial experiments had confirmed and replicated the original lab data, and had demonstrated that the formulated product was more stable than the original microbial fermentate.

However, the initial trials had been scaled up to whole plants in the greenhouse, and included protective applications, with treatment 24 hours before pathogen inoculation, as well as curative applications with inoculation 24 hours after treatment. Here, the commercial references worked well – but for the biofungicide formulation, fungicidal activity was only apparent at such high application rates that the test plants suffered significant leaf damage.

Data from field trials proved equally disheartening. While some of the trials had been a success, an equal number showed little or no fungicidal effect.

Although the formulation had been shown to be stable, and project milestones on the formulation work and efficacy testing were met – the efficacy data was so variable that the goal of a viable competitive product had clearly not been reached.

Figure 5: R&D status for AGCHEMCO’s initial Biofungicide development testing.

***

At the October 2014 AGCHEMCO Executive meeting, results of the business optimization measures were presented.

The implementation of drastic cost-cutting, the culling of low-profit portfolios and the inception of strategic alliances promised a leaner, more effective organization. For the first time in years, the commercial estimates for the company’s agrochemical products were no longer negative.

Following the presentation of the core business results, the status of the Biologicals development project was the next order of business.

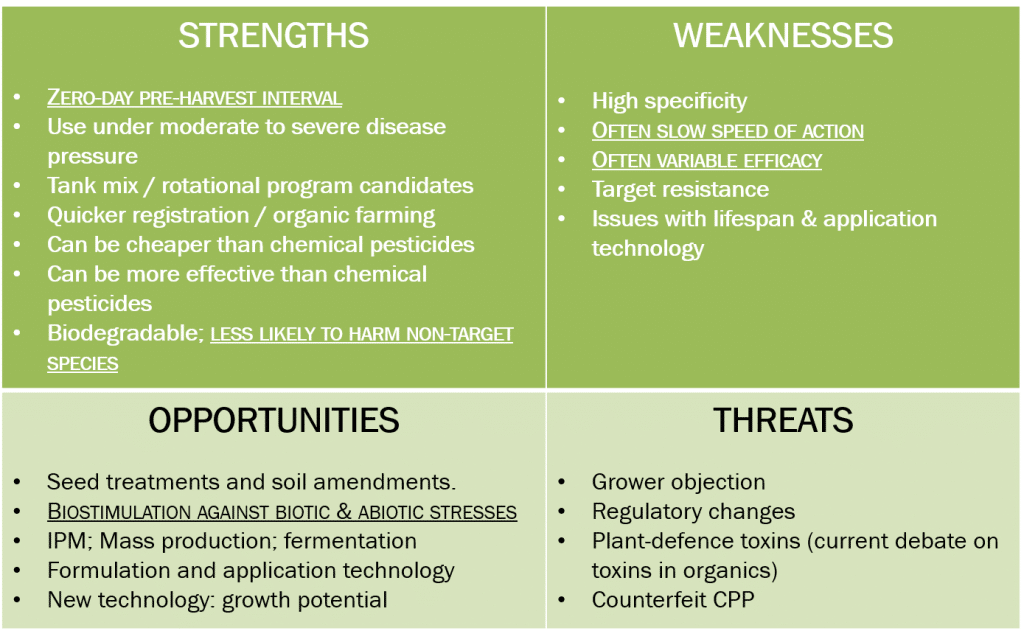

A structured (SWOT) analysis to identify the situational viability of introducing a biological product to AGCHEMCO’s portfolio identified the weakness that gave greatest cause for concern: the variable efficacy of biological crop protection products under field conditions.

Figure 5: SWOT analysis, BioPesticides (AGCHEMCO).

With the decline in their core business halted, AGCHEMCO debated dropping their foray into biological crop protection in order to focus resources on the optimization of their conventional agrochemical portfolio.

To make this decision it would be necessary to analyse what had been learnt, and to consider whether a revised biological development strategy could lead to the successful development of a biological portfolio.

In the second part of this series, the learning process following the implementation of a conventional development strategy is applied to introduce a biological development strategy for the successful introduction of a new biological portfolio.

___________________________________________

Thanks for reading – please help make the BIOSCIENCE BLOG great and enable me to produce more content by LIKING or SHARING this article, making it visible to your network!

***

A little about myself

I am a plant scientist with a background in Molecular Plant Biology and Crop Protection.

20 years ago, I worked at Copenhagen University and the University of Adelaide on plant responses to biotic and abiotic stress in crops.

At that time, biology-based crop protection strategies had not taken off commercially, so I transitioned to conventional (chemical) crop protection R&D at Cheminova, later FMC.

During this period, public opinion as well as increasing regulatory requirements gradually closed the door of opportunity for conventional crop protection strategies, while the biological crop protection technology I had contributed to earlier began to reach commercial viability.

From January 2018, I will consolidate 17+ years of industry experience in BioScience R&D management with my academic research background, to provide independent Strategic R&D Management as well as Scientific Development and Regulatory support to AgChem & BioScience organizations developing science-based products. For more information, visit BIOSCIENCE SOLUTIONS – Strategic R&D Management Consultancy

***

Harry Teicher is the founder of BIOSCIENCE SOLUTIONS and an Authorpreneur, providing organizations with Strategic- and Project Management as well as Development & Communication solutions. He is the Administrator of the INSEAD Strategic R&D Management Alumni Network LinkedIn group. Follow him on Linkedin, Twitter and Facebook.